The History Of Bearings 2

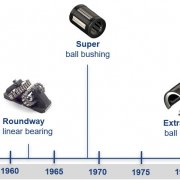

Timeline of Bearings History

Bearings Create Better Life — SuperTembo

2600 BC – The Ancient Egyptians use a form of roller bearings to help move stone pieces during the construction of the Pyramids

40 BC – Early example of a wooden ball bearing supporting a rotating table was retrieved from the remains of a Roman ship in Lake Nemi, Italy

1500 AD – Leonardo da Vinci described a type of ball bearing

1794 – First patent for ball race by Philip Vaughn of Carmarthen, Wales

1839 Isaac Babbit invented an anti-friction alloy with a low melt temperature

1883 – FAG begins grinding balls of equal size and roundness forming the creation of an independent bearing industry

1898 – First patent issued for Timken Tapered roller bearings

1907 – Sven Wingquist of SKF invents the modern self-aligning ball bearing

1917 – U.S. Bearing Manufacturers create an informal group to aid bearing manufacturing for World War I, which led to the founding of ABMA

1934 – AFBMA is incorporated as an organization in the State of New York

1960 – Elasto-hydrodynamic theory explains the mechanism of why bearings and gears work led to advances in grindings precision and ultrasonic equipment

1970– Intel invents the microprocessor and consistent precision control of machine tools impacting both size and life of bearings

In the early 1980s, Pacific Bearing’s founder, Robert Schroeder, invented the first bi-material plain bearing which was size interchangeable with linear ball bearings. This bearing had a metal shell (aluminium, steel or stainless steel) and a layer of Teflon-based material connected by a thin adhesive layer.

History of the Ball Bushing® Bearing